by Maurizia Seggiani and Patrizia Cinelli – Department of Civil and Industrial Engineering

These are some research and development projects that have the implementation of processes as objectives at different scales

innovative treatment and abatement of volatile organic solvents (VOCs) from emissions of

leather painting booths, increasing removal efficiencies compared to those achieved

with traditional plants, designing a plant for the treatment of emissions into air and water

compliant with the Industry 4.0 paradigm and based on a product by district itself used as a sorbent,

with a view to circular economy.

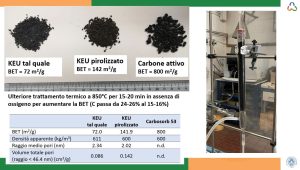

Eco-expansed plant dedicated to the treatment of sewage sludge produced by the Aquarno Consortium

and part of the Fucecchio Tanners Consortium. The final product of the recovery treatment is

the Sintered Granulate (KEU) which, after mixing with calcium carbonate, is used for the production

of inert granulates for construction (HSC) and bituminous conglomerates (HCB) for asphalts.